Making Shoes

Making shoes

Tools, machines and shoemaking equipment charting the evolution of shoe production from hand shoemaking to factory production. The collections include innovative technologies developed over the past two centuries, and representations from the foremost British tool and machinery manufacturers.

Handmaking tools and equipment

The collections include handmade workbenches made by the shoemakers in their home workshops, hand tools made by British toolmakers such as George Barnsley and Sons (Sheffield), handmade shoes and written accounts of the outwork system.

The first Clarks footwear was made in the 1830s. Hand shoemaking continued at Clarks for decades after the introduction of machinery to the shoemaking process. The last handsewn shoes were made by outworker Frank Parsons of Somerton in 1941. Making a shoe by hand remained an important training for generations of shoemakers at Clarks, including those employed in factory production.

Design catalogues

The footwear and trade catalogue collections represent a rich resource for today’s designers. Illustrated designs, technical specifications and significant collections of sample shoes, some of which were never made as Clarks products. A notable example is an assemblage of handmade prototypes linked to Derek Radford (Clarks designer), who designed the Clarks Polyveldt. Drawings and sample shoes also represent Clarks designers’ submissions to the Footwear Organiser competition

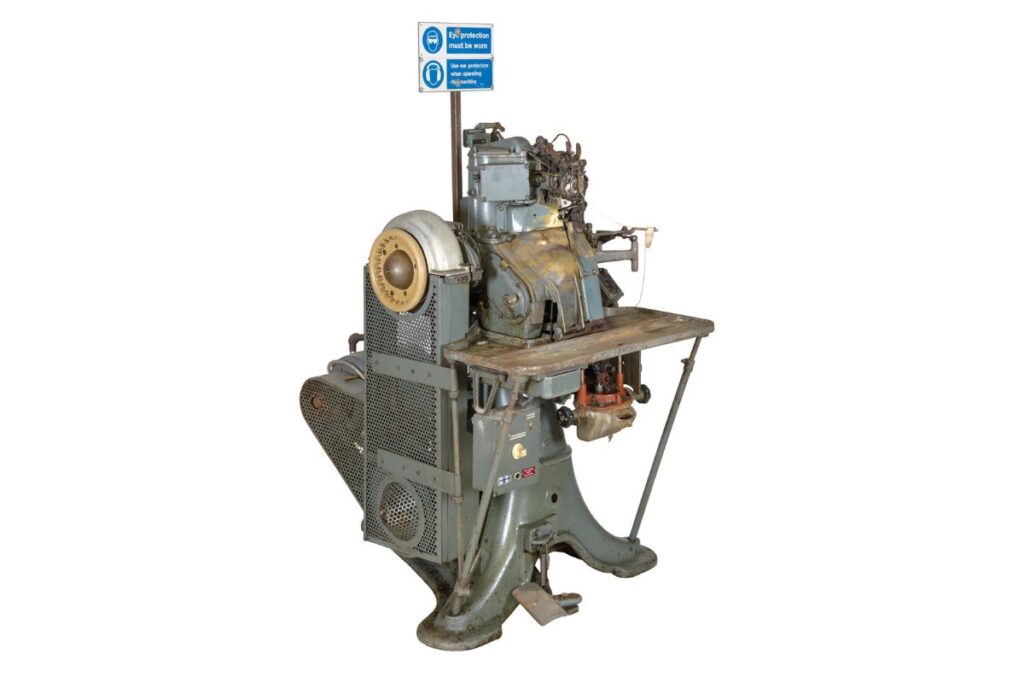

Shoemaking machinery

The shoemaking machinery collection comprises nearly 600 machines used in footwear manufacture, mainly by Clarks, ranging in date from the 1860s to the1990s.

These include machines made by prominent British and international manufacturers such as the British United Shoe Machinery Company, Standard Engineering, Moenus, Junker & Ruh, Pfaff, Singer, and Clarks’ own machine engineering branch, CIC (Ralphs) Engineering in Bath.

Some machines such as the Mediano CEMA injection-moulding machine (1949) are notable in their own right. In other cases, complete groupings such as the Clarks ‘Desert Boot’ line salvaged from the Weston-super-Mare factory upon closure in 2001 are unique survivors of industrial history.

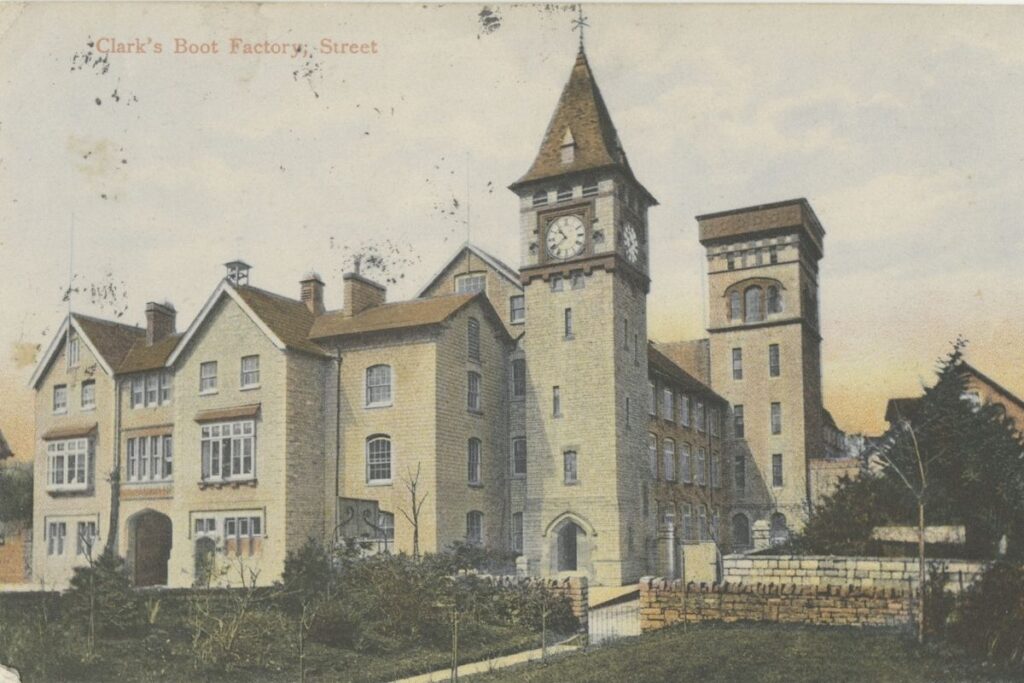

Clarks Factories

These factories and their communities are represented in the collections in the form of personnel records, photographs, factory publications, architectural plans – and of course, the shoes that were made in them. Clarks’ earliest factory building still stands in Street, at 40 High Street. From the 1930s Clarks opened new factories outside of Street: in Dundalk (Ireland), and across Somerset and the south west of England and Wales: Bridgwater, Shepton Mallet, Plymouth, Midsomer Norton, New Tredegar, Minehead, Weston-super-Mare, Bath, Yeovil, Warminster, and Castle Cary.

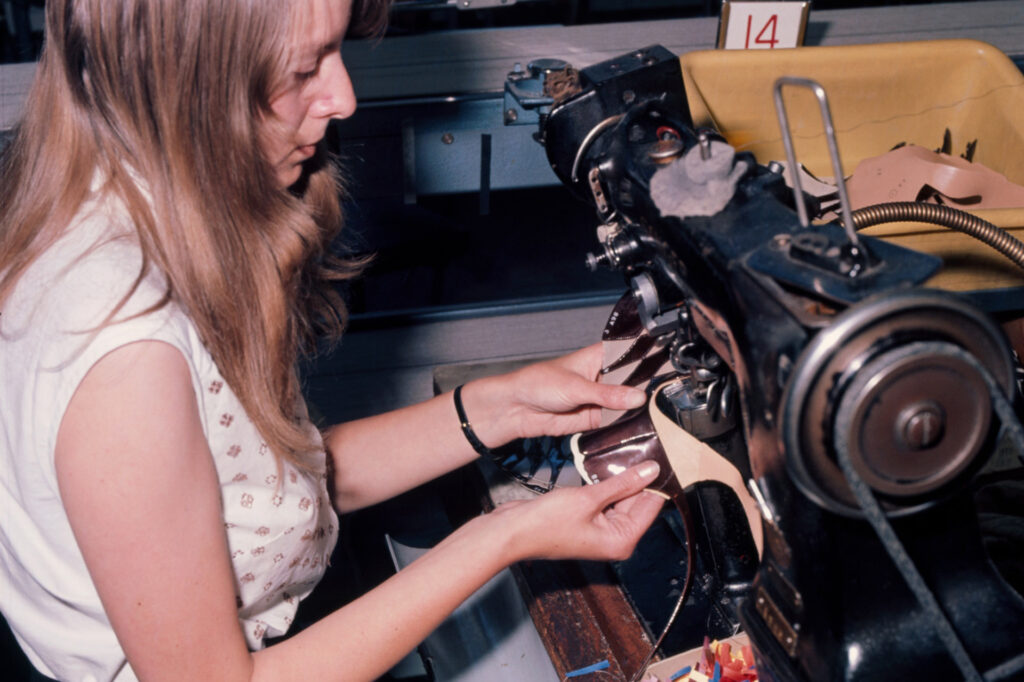

Shoemakers

Woven through the collections are the stories of the shoemakers themselves, from the shop floor operatives to the company directors. Photographs, written reminiscence, oral histories, factory newspapers and thousands of artefacts make up an important record of one of Britain’s major industries and the people whose specialist knowledge, skill and lived experience were its lifeblood.

This is a growing area of the collection which we are actively seeking to expand, collecting from and with the communities which once centred on Clarks factories